C-MOR™ DRIVES DOWN CARBON EMISSIONS THROUGH STATE-OF-THE-ART GREEN HOUSE GAS REDUCING TECHNOLOGY – HELPING CUSTOMERS ACHIEVE NET-ZERO EMISSIONS

More and more companies within the Energy Sector have taken a Customer First Approach by setting stringent goals to achieve Net-Zero Emissions. The production, transport, processing and consumption of oil and gas products accounts for 60% of all global greenhouse gas emissions, with a quarter of those (15%) directly attributable to the oil and gas industry. Upstream operations account for two-thirds of sector-specific emissions. By deploying energy efficiency and circular solutions, companies can leverage less carbon-intense clean electricity, displace diesel with gas or electricity alternatives, and reduce waste energy consumption.

One of the present methods of illuminating Oil and Gas locations at night involves the use of lighting systems powered by diesel generators and HPS Lamps which contribute to air pollution, vibrations, and noise in the work environment.

Emissions typically include discharges associated with the energy used to power operations. A company can reduce its emissions by: lowering its energy demand; replacing fossil energy sources to lower carbon-intensity electric power.

At C-MOR Energy Services™, we understand this industry’s needs and have developed net zero emission lighting technology to help our customers achieve their goal, while improving worksite safety and environmental stability for future generations.

C-MOR™ Lights can be used for utility infrastructure construction; routine maintenance and repairs in noise sensitive areas; power plant shut downs; recovery following natural disasters, or an electric grid disruption, etc.

The Multi-Patented Crown Jewel™ and Guardian™ Gen 3 Lighting Systems have an important Advantage over Diesel-Powered Lighting Trailers in that C-MOR’s produce Little to no Greenhouse Gases or Noise.

C-MOR’S NET ZERO EMISSIONS LIGHTING SYSTEMS HAVE SIGNIFICANT ENVIRONMENTAL BENEFITS:

- Lower maintenance requirements as compared to Diesel powered lighting trailers.

- C-MOR’s systems not only increase the use of alternative energy but also provide environmental benefits which result in lowered costs and safer worksites.

- The Crown Jewel™ reduces highway traffic by eliminating the need for delivery or pickup of Light Towers between locations.

- Produce little to no Greenhouse Gases or Noise.

- Each HPS lamp contains 10-50 milligrams of mercury — enough to poison an entire classroom of children above threshold limits. Using our High Efficiency LED’s, avoids this.

- Reduces Road Traffic and Dust Pollution.

- Zero Spill Potential

- Due to their lower energy consumption, LED luminaries account for the least amount of CO2 emitted into the air, as compared to other lighting sources.

- LED lights realize a 65% reduction in energy consumption compared to sodium or mercury lamps and have a longer service lifetime.

- Improves labor efficiency by eliminating fuel and maintenance trips.

The Crown Jewel™ and the Guardian Gen 3™ Lighting Systems are far superior to Metal Halide Light Towers which are powered with diesel generators. Our LED lights are environmentally friendlier, resulting in Green House Gas Emissions Reductions.

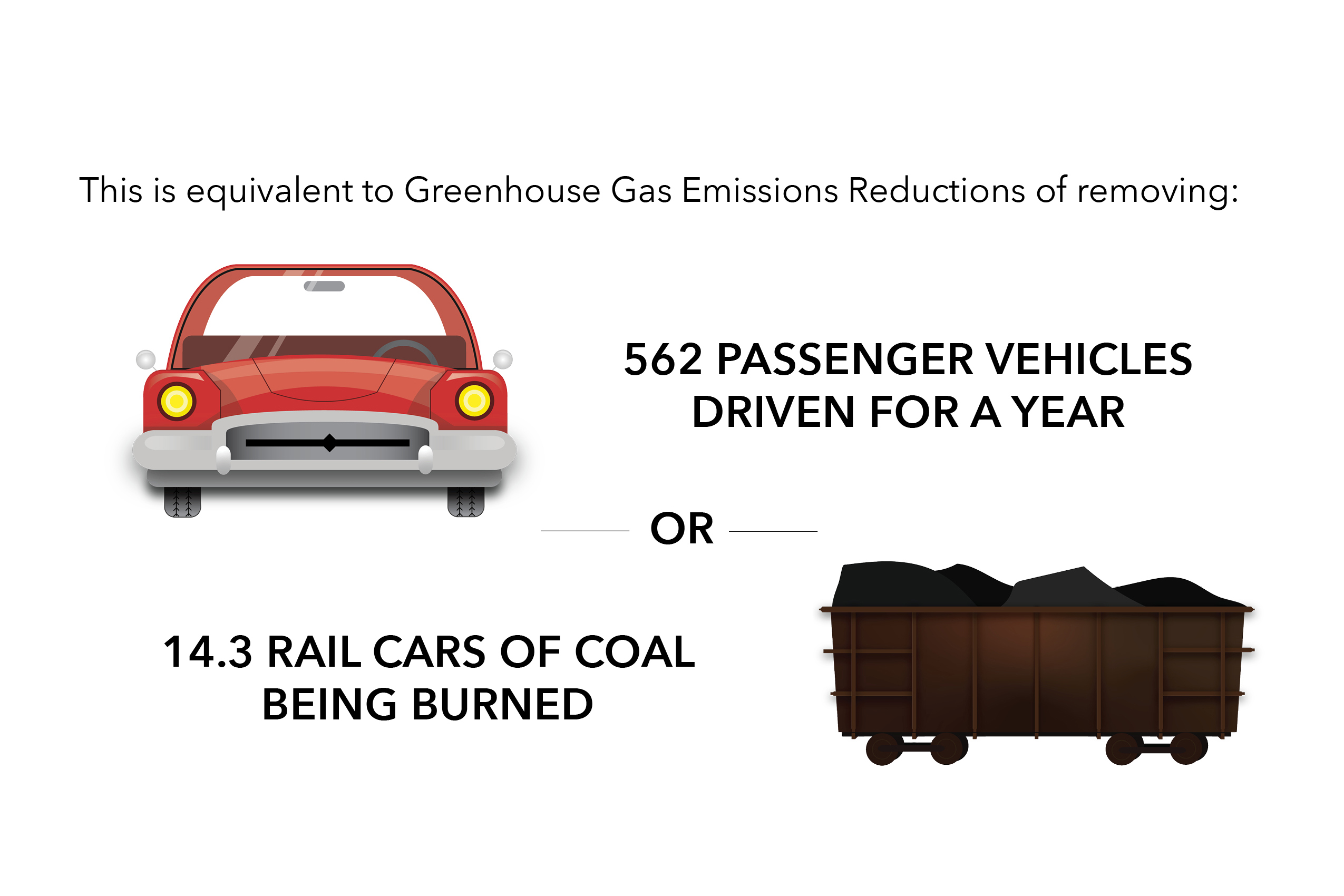

A recent study was completed for an operator with a 6 Drilling Rig program over 1 years’ time. The study found that by utilizing our lighting system, rather than standard lights towers Green House Gas Emissions would be REDUCED by approximately 630 TONS from the lights alone and another 2,869 tons from the REDUCTION in Diesel Fuel or 3,500 TOTAL TONS REDUCED in Green House Gas Emissions annually.

Energy efficiency and carbon reduction technology are the ways of the future for the oil and gas industry. Take the first step today and contact us about ordering eco-friendly oilfield lighting to provide your employees with safe and effective lighting, all while saving your company money.

Emission Reduction from Switching to Our Lights

LED Lights + Reduction in Diesel Fuel

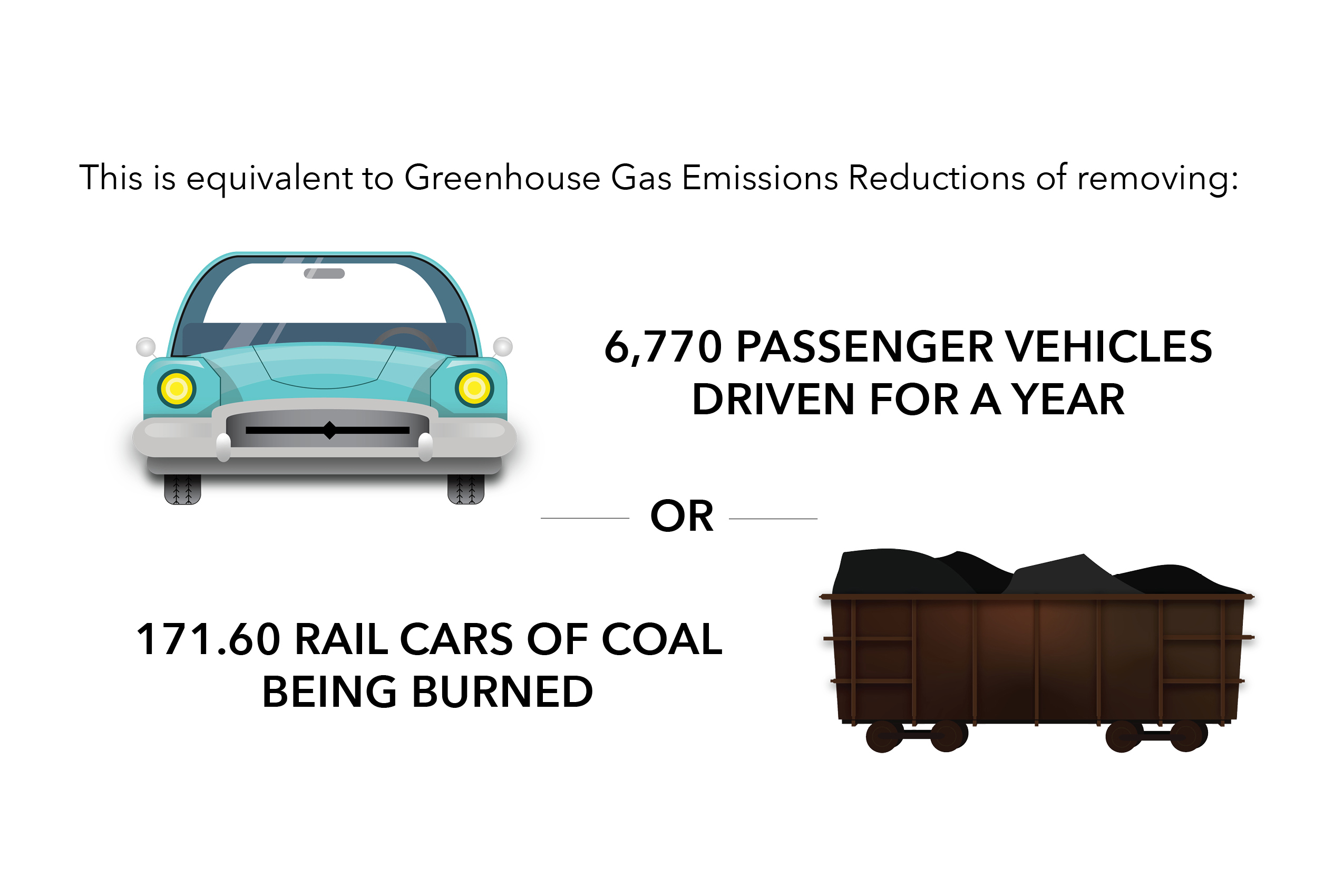

On 6 Frac locations this would equate to reducing Green House Gas Emissions by nearly 7,560 tons from switching to LED lighting and nearly 34,428 tons from the Reduction in diesel fuel for a total combined REDUCTION of 42,000 TONS in Greenhouse Gas Emissions.

If Green House Gas Emission Reductions, Cost Savings and Increased Safety are your goals, then the Crown Jewel™ and the Guardian™ Gen 3 Lighting Systems are a must over the use of Diesel-Powered Light Towers